The Rise of Expandable Container Houses in Modern Construction

Growing Demand for Modular and Prefabricated Construction

Global modular construction markets are expected to expand around 6.3 percent each year until 2030, mainly because we're facing serious housing shortages and rising labor costs across many regions. Container homes stand out as leaders in this movement, since they come with ready-made parts that simplify designs but still let builders tweak things for specific locations. Some studies on how efficient prefabrication really is show that using these techniques cuts down on wasted materials by about 32 percent. Plus projects get finished much faster too, somewhere between 40 to maybe even 60 percent quicker than regular buildings made from bricks and mortar. That kind of speed makes all the difference when time matters most.

How Expandable Container Houses Redefine Spatial Flexibility

Telescopic walls and multi-directional expansion mechanisms enable these units to gain 110–150% more interior space without increasing their permanent footprint. This adaptability allows seamless transitions between compact transport configurations and spacious living or working environments–ideal for vacation rentals with seasonal demand or startups needing scalable office solutions.

Factory-Based Construction: Lower Waste, Faster Build Times

When manufacturing takes place in factories instead of on construction sites, there's no waiting around for bad weather to pass. The quality stays pretty much the same throughout too, since about 92% of all parts get cut with machine-like precision before they ever leave the facility. What's really impressive is how we handle waste materials. Most steel scraps get recycled at around 98% efficiency, which beats the usual 65% recycling rates seen in traditional demolition projects. Another big plus comes from our parallel workflow system. While crews work on preparing foundations and utility connections right at the project site, construction teams build modular units elsewhere. This clever approach cuts down on scheduling problems by roughly half, which makes these expandable container homes perfect when communities need quick shelter solutions after disasters or during housing crises.

Design Flexibility and Customization Options for Expandable Container House Projects

Modular Expansion and Reconfiguration for Evolving Needs

These homes support long-term adaptability through modular add-ons and reconfigurable layouts. Users can start with a compact single-unit design and later expand as family size grows or business needs change. This scalability reduces initial investment and future-proofs structures against evolving usage requirements.

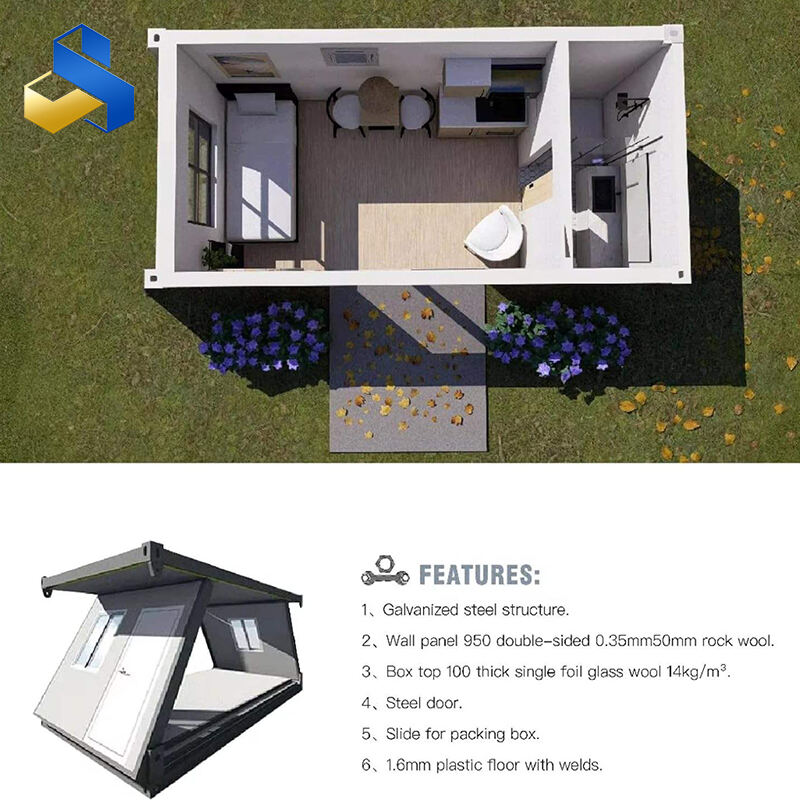

Interior Layouts Optimized for Residential and Commercial Use

The same structural framework supports diverse functions through smart space planning. Open-concept living areas with movable partitions suit residential comfort, while soundproofed office pods with integrated wiring meet commercial demands. Designers often include multi-level mezzanines and foldable furnishings to maximize usable space without expanding the building’s footprint.

Tailoring Aesthetics and Functionality to Client Requirements

The exterior options go from rough wood panels to shiny metal surfaces, depending on what kind of look people want and how tough the local weather gets. Some buildings get special roofs ready for solar panels where there's lots of sun, while others have stronger fasteners in places prone to storms along the coast. Inside, folks can customize things pretty well these days. Smart home tech is becoming standard, plus there are options for wheelchair access and different types of insulation based on whether it's cold or hot outside. The goal is simple really make sure whatever looks good also works properly for whoever lives there.

Applications Across Industries: From Housing to Emergency Relief

Affordable and Rapid-Deployment Housing Solutions

Container homes that can expand are proving to be an affordable solution for the world's growing need for housing. Real world examples from places like Kenya and Mexico show these structures provide decent shelter while cutting costs by around 30 to 40 percent compared to regular building methods. What's more, putting them all together takes just about eight weeks from start to finish. The speed and savings make these containers work well whether building up city spaces or setting up new villages in remote areas. Looking ahead, this kind of fast-track construction fits right into what industry experts predict will be an $114 billion market for modular buildings by the end of the next decade.

Pop-Up Retail and Flexible Office Spaces

More and more retailers along with new business ventures are turning to those expandable container units as temporary spots for stores and shared work areas. The fact that these containers come in modules makes them really attractive for companies such as local coffee places or small fitness centers wanting to check out a market before signing any long term lease agreements. What's interesting is how much waste gets avoided too – almost all the materials stay useful even after moving locations somewhere else. According to recent data from a commercial real estate report released in 2023, around two thirds of companies today actually prefer having adaptable setups instead of traditional brick and mortar structures.

Emergency and Humanitarian Housing: Speed and Scalability

After Cyclone Ana hit Malawi back in 2022, these expandable container units were able to accommodate around 15 families each day, which was roughly 70 percent quicker compared to regular emergency shelters. Built with strong steel frames that can handle winds up to 120 miles per hour, plus they stay comfortable in temperatures ranging from minus 20 degrees Celsius all the way up to 50 degrees. What makes them so useful is their speed of setup, something that really matters when we consider how many people get displaced by disasters every year. According to United Nations data, there have been approximately 37.9 million such displacements annually since 2020 started. That number alone shows why having fast deploying shelters becomes absolutely critical during these situations.

Sustainability and Environmental Impact of Expandable Container House Construction

Recycled Materials and Resource-Efficient Building Practices

Expandable container houses embody circular construction by repurposing decommissioned shipping containers. Over 60% of structural steel comes from existing containers, avoiding 12–15 tons of CO₂ emissions per unit compared to conventional builds. Standardized modular designs further enhance sustainability by reducing steel cutting waste by up to 40%.

Energy Efficiency Through Smart Insulation and Passive Design

Advanced insulation transforms thermally conductive steel into energy-efficient spaces. Typical models achieve 30–35% lower heating and cooling loads through:

- Vacuum-insulated panels (R-30+)

- Triple-glazed argon-filled windows

- Passive solar orientation aligned with seasonal sun paths

These features allow some units to meet Passivhaus certification standards while maintaining 80% natural daylight penetration.

Comparing Carbon Footprints: Container vs. Traditional Construction

A 2023 lifecycle analysis shows expandable container houses generate 35% less embodied carbon than wood-frame homes and 52% less than concrete structures. Key data points include:

| Metric | Container Home | Traditional Home |

|---|---|---|

| Material production | 8.2 tCO₂e | 19.1 tCO₂e |

| Construction phase | 1.1 tCO₂e | 3.8 tCO₂e |

| 50-year maintenance | 4.3 tCO₂e | 11.6 tCO₂e |

While transportation emissions remain a consideration, centralized factory production offsets 20–25% of delivery impacts through optimized logistics.

Debating True Sustainability: Challenges and Considerations

Even though they cut down on material waste somewhere around 60 to 70 percent, expandable container homes still get criticized for their sustainability issues. When builders make changes like cutting out sections for insulation, this actually reduces the amount of steel that can be recycled by roughly 15 to 20%. Another problem is zoning laws - most big cities just don't have regulations in place that allow people to live in containers. And let's not forget about energy performance either; different manufacturers track this stuff completely differently, making comparisons pretty much impossible. Some industry players are trying to fix these problems by creating hybrid designs that mix modular construction techniques with natural materials like bamboo or reclaimed wood. These new approaches keep costs reasonable while slowly but surely moving toward better environmental results over time.

Economic Advantages and Cost-Effectiveness of Expandable Container Houses

Lower Upfront Costs Through Prefabrication and Minimal Foundations

Container houses can cut upfront costs anywhere from 30 to 50 percent when compared to building conventionally. This cost savings comes mainly from the fact that these homes are built in factories rather than on site, plus they need much simpler foundations. When it comes to materials, prefabricated construction generates far less waste. Think about it: construction waste makes up around a quarter of all landfills worldwide. Another big plus is avoiding those frustrating weather delays that drive up hidden costs during traditional builds. According to industry numbers, going modular saves between $75 and $150 for every square foot. And specifically for container homes, foundations require about 60 percent less concrete than standard construction methods do. These practical advantages make expandable containers an increasingly attractive option for budget conscious builders looking to minimize both financial outlay and environmental impact.

Reduced Labor and Onsite Assembly Time

Most projects end up wrapping up somewhere between 4 to 8 weeks quicker when we run things in parallel. Think about it this way: while crews are getting ready at the actual construction site, the building modules are already being put together elsewhere in factories. The numbers tell an interesting story too. Labor hours drop dramatically, somewhere around 40% to even 70% in some cases, because those factory settings just work better for efficiency. Take a look at what happened last year with container homes versus traditional wood frame buildings. One particular study found they needed only about 17% of the onsite workforce compared to similar projects. That means big savings on payroll and also cuts down on accident risks since there's simply less traffic around the worksite.

Long-Term Value via Durability, Relocatability, and Low Maintenance

Corten steel exteriors stand up to corrosion really well and can handle some pretty harsh weather conditions too, even surviving winds blowing at around 120 miles per hour. Over the course of three decades, these exteriors need about 90 percent less maintenance work than traditional wood siding would require. What makes this material especially interesting is its modular design feature which lets buildings be completely taken apart and moved somewhere else within just 72 hours. This kind of flexibility proves incredibly useful when setting up temporary housing solutions or running mobile business operations from different locations. Plus there's the added benefit of energy efficient insulation that cuts down on heating and cooling expenses somewhere between 18 to 35 percent every year. And because all the parts are standardized, fixing things becomes much simpler without needing those expensive specialist contractors who charge premium rates for their services.

FAQ about Expandable Container Houses

What are expandable container houses?

Expandable container houses are modular structures that can increase their interior space through mechanisms like telescopic walls, offering adaptable living or working environments.

How do expandable container houses benefit in emergency situations?

Due to their rapid deployment capabilities, expandable container houses provide quick shelter solutions during disasters, offering durable and comfortable living conditions.

Can expandable container houses be customized?

Yes, they can be tailored in terms of interior layouts, aesthetics, and functionalities to meet specific client requirements and environmental conditions.

Are expandable container houses environmentally sustainable?

Expandable container houses promote sustainability by repurposing shipping containers and minimizing waste, though they face challenges in material recycling and zoning laws.