Urbanization and Mobility Drive Demand for Portable Housing Solutions

The rapid growth of cities around the world is putting serious strain on housing systems everywhere. According to UN-Habitat reports from last year, almost 7 out of 10 people will be living in urban areas by 2035. That's where expandable container homes come into play as they offer flexible living options that can move with changing city populations and workers who need temporary accommodations. These containers work especially well in crowded neighborhoods where building normal houses just isn't feasible due to space constraints or cost issues. Cities struggling with not enough housing have found these modular solutions to be quite effective when trying to meet immediate needs while planning for long term fixes.

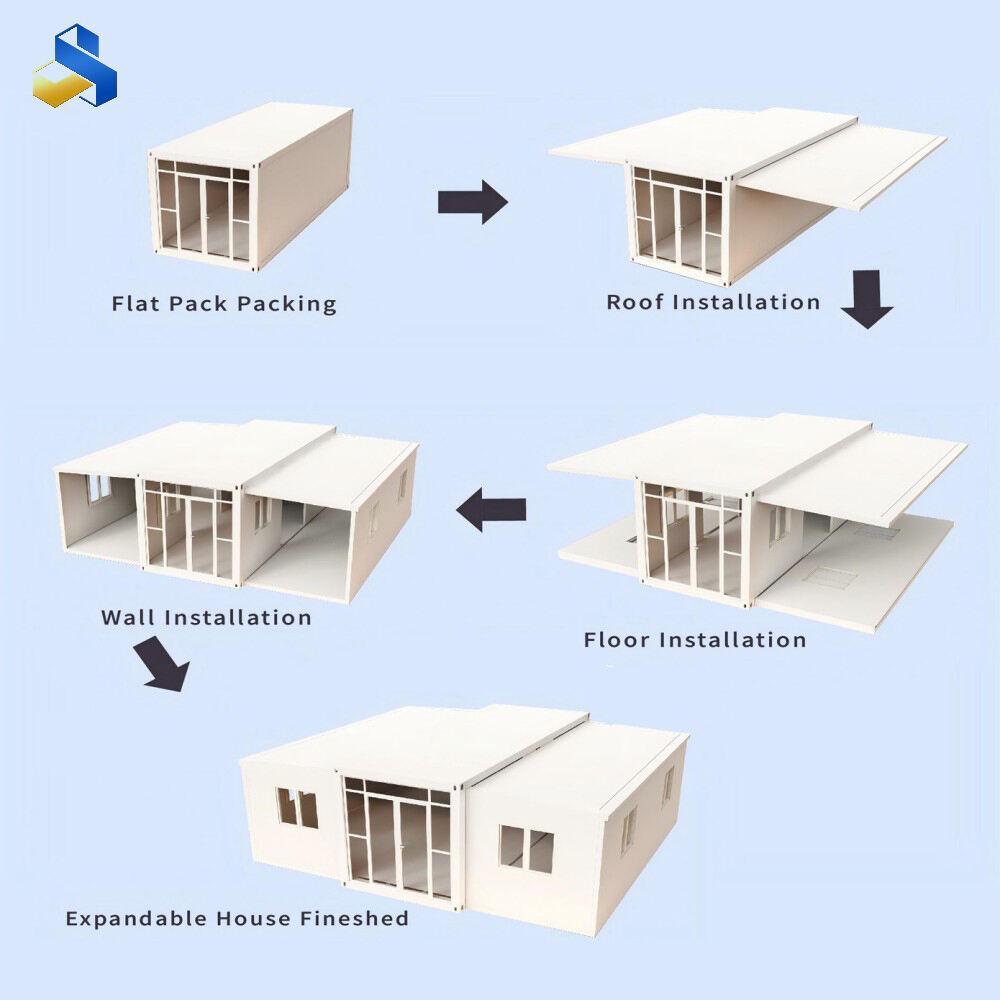

Modular Design Enables Flexibility, Scalability, and Rapid Deployment

Expandable container houses are basically built using modular engineering principles, creating buildings that come flat packed and then expand right at the construction site. The standard steel frames fit together pretty precisely too, so these homes can actually expand from around 20 square meters up to about 60 square meters within roughly two days. What makes this approach really interesting is how flexible it gets. Residential units aren't stuck in one configuration either; they can be stacked vertically when building apartment complexes or connected side by side to form community spaces like schools or clinics. Some recent improvements in folding wall technology have pushed things even further, letting builders triple the usable space while still maintaining solid structural strength throughout the entire process.

Real-World Applications in Disaster Relief and Remote Living

Last year when those big hurricanes hit Florida and forced around 12,000 people out of their homes, expandable container villages came to the rescue pretty quickly. Within just three days after the storm made landfall, folks had access to decent temporary shelter that could actually stand up against bad weather. Down under in Western Australia, mining outfits have been putting these same containers to work too. They set up portable worker camps that don't mess with the local environment as much as traditional setups do. And get this – because they're so well insulated and can operate without being connected to power grids, these containers are perfect for research stations way up north in the Arctic Circle where temperatures plunge to minus 40 degrees Celsius but scientists still need consistent warmth inside.

Portability and Fast Deployment of Expandable Container House Designs

Modular and Foldable Structures Simplify Transport and On-Site Assembly

Container houses that can expand and collapse save a lot of space when being transported, shrinking their size by about 60% compared to regular modular units. The clever folding systems let builders pack several pre-made parts onto one standard truck trailer, which cuts down on shipping expenses roughly 35%, according to research from GZU in 2023. This kind of smart design means construction teams can get housing solutions out to far away places or areas hit by disasters without needing fancy transport equipment. When looking at actual field data from Nepal's mountain regions during the floods in 2022, we saw delivery times drop nearly half for these expandable containers compared to traditional methods.

Short Construction Timeline: As Fast as 15 Days from Factory to Occupancy

When it comes to factory built components, there's simply less need for on site labor these days. Mechanical expansion systems have made things pretty straightforward too. A team of just four workers can get a 300 square foot unit up and running in less than two days flat. The big names in the business are already delivering ready to occupy units within 15 days after someone places an order, which is roughly three quarters quicker than what we used to see with traditional stick built methods back in the day. Real estate developers are seeing some serious savings too. On average they're pocketing around $18k per unit because their projects aren't held up by rain or snow anymore thanks to those controlled manufacturing conditions inside factories where everything stays dry and predictable.

Case Example: Mobile Clinics Using Portable Expandable Container Houses in Rural Areas

- Deployed 12 expandable clinics across sub-Saharan Africa (2021–2023)

- Units feature integrated solar panels and water purification systems

- Each clinic expands from 160 sq. ft. (transport mode) to 480 sq. ft. (operational mode)

- Reduced setup time from 3 weeks (traditional structures) to 3 days

- Patient capacity increased 40% through smart spatial configurations

This approach demonstrates how rapid-deployment container architecture can scale critical infrastructure while maintaining budget constraints typical in low-resource settings.

Sustainability Advantages of Expandable Container House Construction

Recycling Shipping Containers Reduces Waste and Carbon Footprint

When old shipping containers get turned into homes instead of sitting in ports or getting scrapped, we keep around 1.8 million tons of steel out of landfills each year. According to Global Construction Review last year, this approach cuts down carbon emissions by roughly two thirds compared to producing new steel. What makes this work so well? These containers already have walls and roofs, so builders don't need to start from scratch with raw materials. Plus, manufacturing these converted homes takes far less energy than building conventional houses. Most containers only last about 12 years before they're retired, but when properly retrofitted for living spaces, they can stick around for four decades or more. That means each repurposed container avoids putting about 20-25 metric tons of CO₂ into the atmosphere over its extended life, which explains why more cities are embracing this practice as part of their green building strategies.

Net-Zero Energy Developments: Case Study from Australia

A group of Australian builders managed to hit net zero energy for 37 expandable container homes across various locations. They did this by installing around 14 kW worth of solar panels on each unit and using special phase change materials for insulation. Pretty impressive stuff considering these homes cut their reliance on the power grid down to just 8% even when temperatures outside hit scorching 45 degrees Celsius during summer months. According to reports from the Melbourne Net Zero Housing Initiative, families living in these eco-friendly containers save approximately $1,200 every year on utilities alone. This shows that modular construction methods can actually work wonders when it comes to making renewable energy solutions accessible and practical for wider adoption.

Green Certifications Emerging for Sustainable Modular Housing

Leading certification bodies now recognize expandable container systems under rigorous sustainability criteria. The BRE’s BREEAM Modular 2024 Standard awards top ratings to units using ₵¥85% recycled steel and non-VOC insulation. Manufacturers achieving this certification report 22% faster permitting approvals, incentivizing greener construction practices.

Balancing Insulation Challenges with Eco-Friendly Materials

New materials such as aerogel blankets and hempcrete are making real progress against the problem of thermal bridging that plagues steel structures. These innovations can boost insulation values all the way from around 6.5 up to impressive numbers like 14. According to research published last year, when builders combine recycled denim insulation containing about 12 percent post-consumer waste material with expandable container walls, homeowners actually see their heating bills drop by roughly one third in areas with moderate weather conditions. Looking at what's happening in the world of modular homes right now, there's growing interest in using sheep's wool composites instead of traditional fiberglass options. Not only does this natural material work well for insulation purposes, but it also breaks down over time, which means we're not just building better houses today but creating something that won't burden future generations either.

FAQ

- What are expandable container homes? Expandable container homes are modular housing units that can be transported flat and expanded on-site, offering flexible and rapid living solutions.

- How do expandable container homes help in urban housing? These homes offer a quick solution for housing shortages in urban areas by providing scalable and flexible living options that can adapt to population changes.

- Where are expandable containers commonly used? They are widely used in disaster relief, remote areas, and transitional housing programs due to their quick deployment and portability.

- Are expandable container homes environmentally friendly? Yes, they utilize recycled shipping containers, reducing waste and carbon emissions, and can integrate renewable energy solutions like solar panels.

- How cost-effective are expandable container homes compared to traditional homes? They tend to have lower labor and material costs, faster construction timelines, and offer significant savings on long-term maintenance.

Table of Contents

- Urbanization and Mobility Drive Demand for Portable Housing Solutions

- Modular Design Enables Flexibility, Scalability, and Rapid Deployment

- Real-World Applications in Disaster Relief and Remote Living

- Portability and Fast Deployment of Expandable Container House Designs

- Sustainability Advantages of Expandable Container House Construction

- FAQ